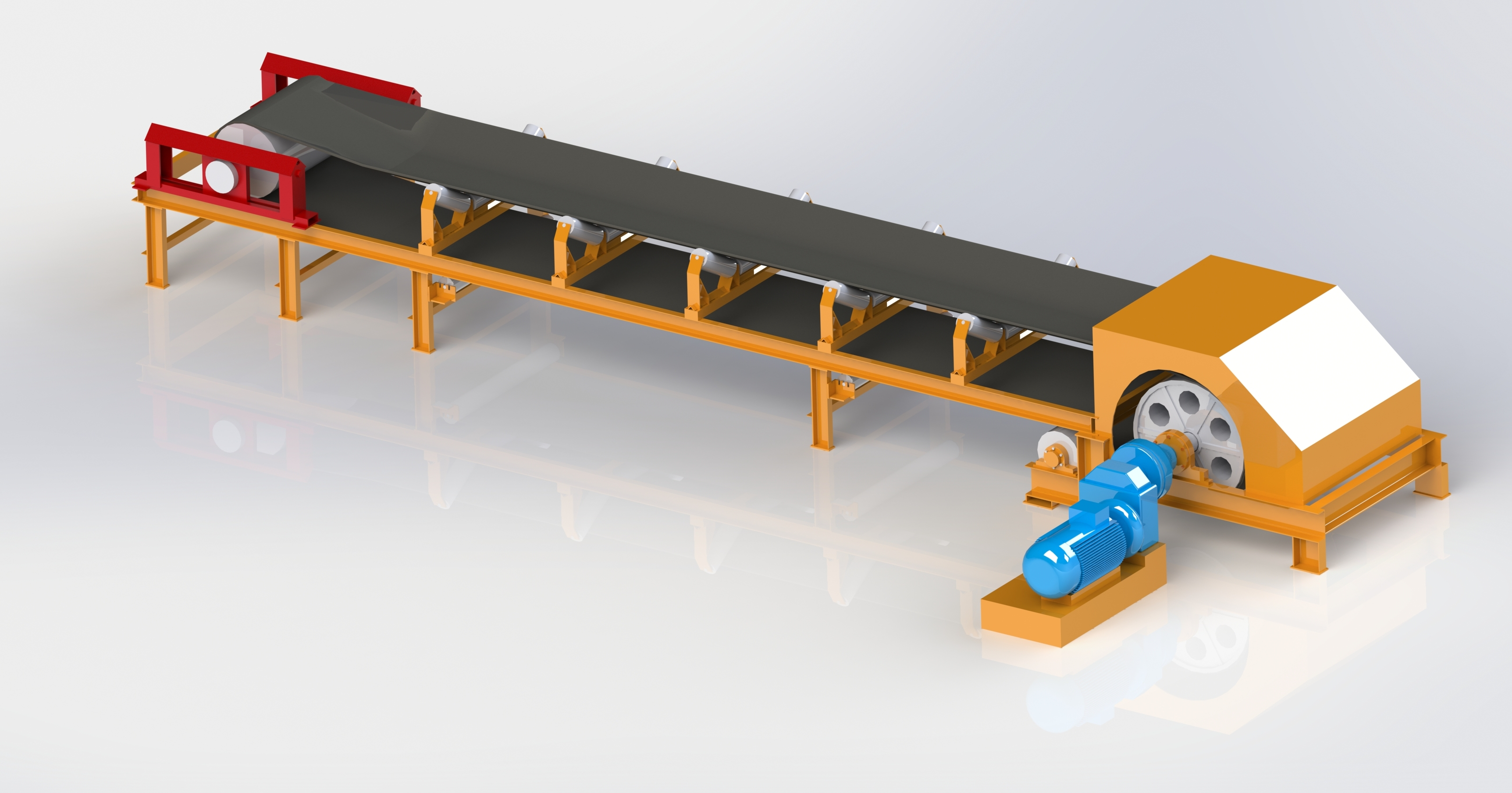

DETECT ABUSE- AND DAMAGE ON A REAL-TIME BASIS

Damage and abuse can result in catastrophic failures- and system downtime.

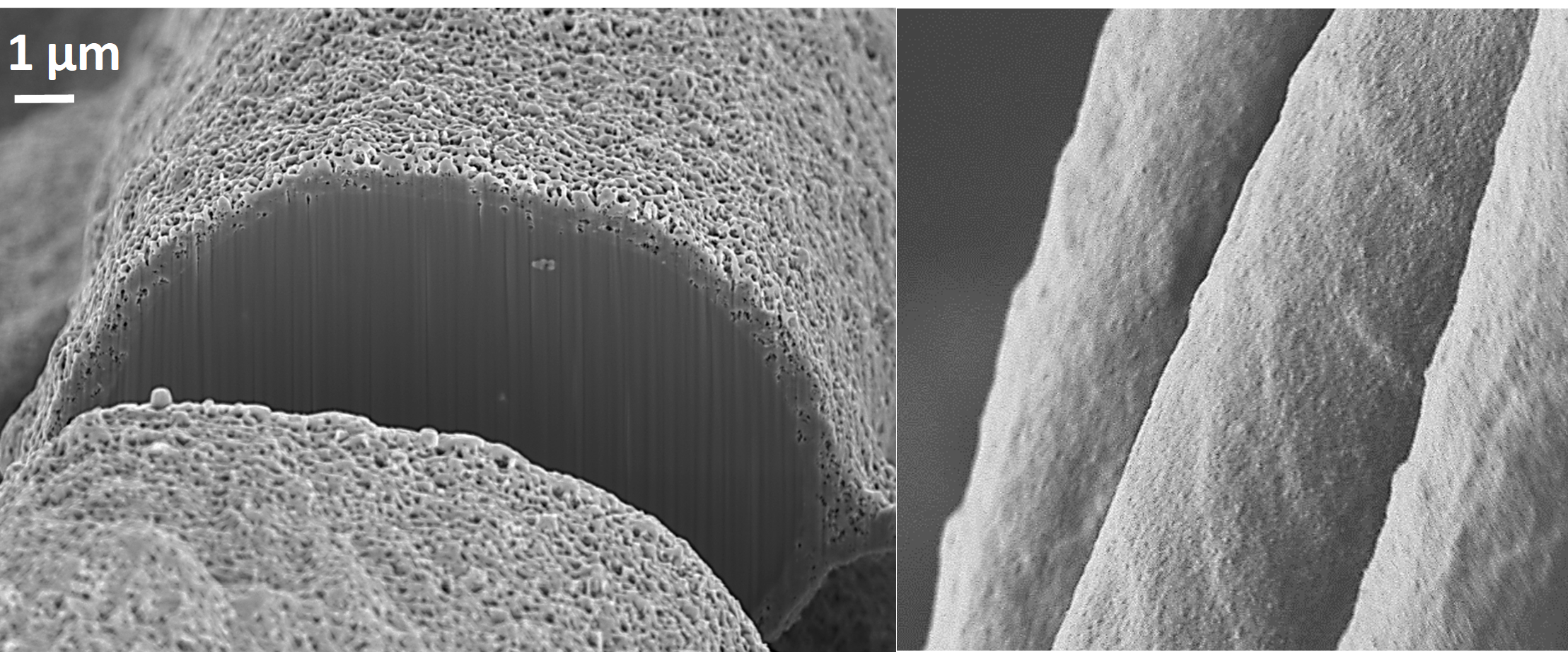

The MCET Smart Sensor solution is to utilize distributed sensing based on networks of conductive nanostructured carbon that can monitor large or targeted areas anywhere on the structure on an ongoing basis.

USE BIG DATA TO UNDERSTAND FAILURE MODES

MCET CNT technology can sense strains, cracks, or pitting defects at any point in the structure- on a 24/7 basis.

Our carbon nanotube sensing technology can both accurately detect cracks and measure their rate of growth in both metallic and non-metallic tanks. This solution can either be applied as an aftermarket solution or can be integrated with the tank when built.

NON-INVASIVE TECH

Our patented technology can be either applied on the surface of a component or integrated into the development process- with no "FOD" (foreign object damage)

PREDICTIVE MAINTENANCE

We can monitor and predict many factors that affect structural integrity, such as pressure, integrity and damage in a wide area in the component- on a 24/7 basis.