STOP THE UNPLANNED SHUTDOWN

While systematic monitoring has increased in importance, structural monitoring, including gasket, seal, diaphragm, and other solid component structural health monitoring has limitations in time or sensing areas- or both. As a result, once a breakdown happens, forced shutdowns must be initiated- which loses money and manufacturing time.

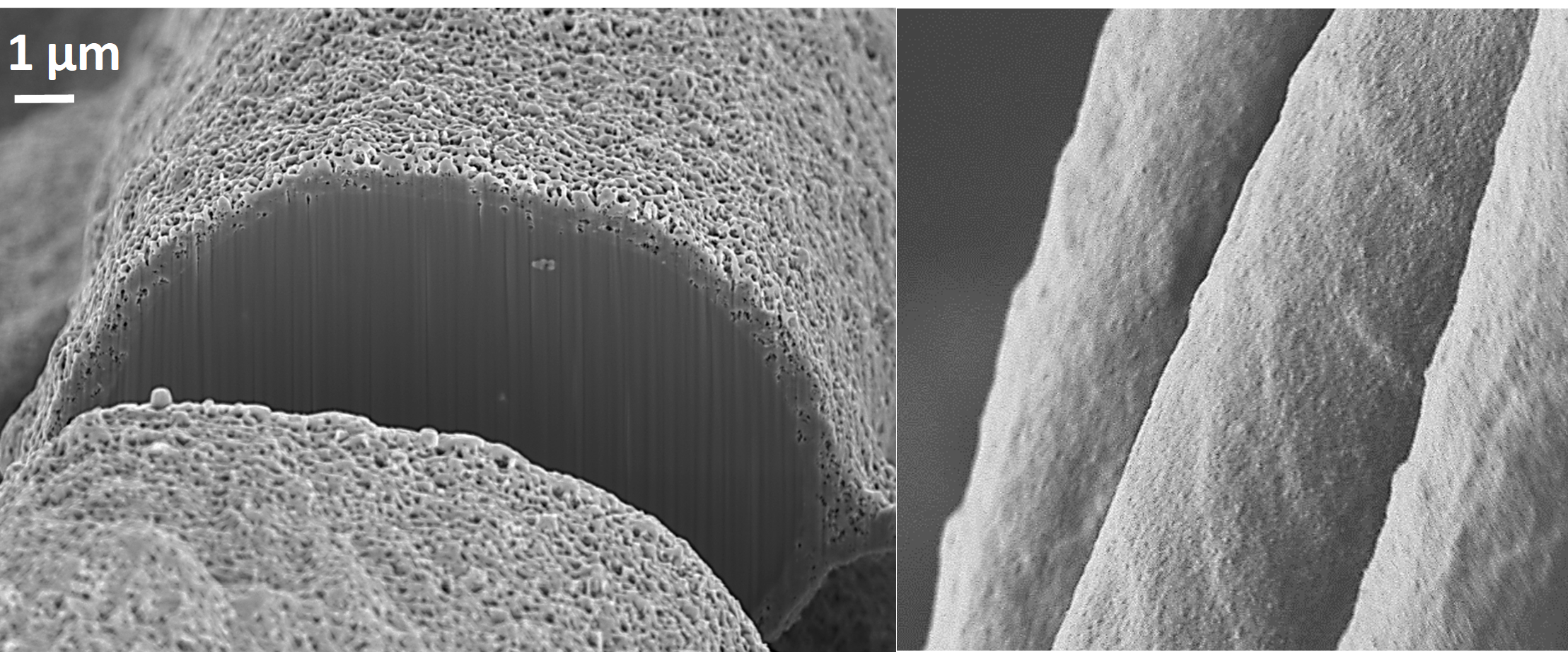

MCET has developed technology that can provide real-time structural monitoring of pressure and structural integrity by using non-invasive embedded sensor technology that uses multi-walled, nanotube technology.

CUTTING-EDGE DAMAGE DETECTION TECHNOLOGY

While structural failures represent both a financial and safety risk for a variety of industries, failure mode assessment is most likely undertaken after the structural failure occurs, and any repairs or recommendations are made because of the failure and the damage has occurred.

Our patents can meet that challenge- and predict the failure before it occurs.

NON-INVASIVE TECH

Our patented technology can be either applied on the surface of a component or integrated into the development process- with no "FOD" (foreign object damage)

ULTRA-WIDE SENSING RANGE

MCET CNT technology is high-temperature resistant and can detect pressures up to 60 MPa (8,700 PSI) or more- well suited to critical industrial applications.